Ulayini wokukhiqiza udaka olomile ome mpo lwe-CRL-H

Imininingwane Yomkhiqizo

Isingeniso

Umugqa wokukhiqiza udaka olomile ome mpo

Umugqa wokukhiqiza udaka ome mpo we-CRL-H uchungechunge lokukhiqiza oluhlanganisiwe lokumisa isihlabathi kanye nokukhiqizwa kodaka olujwayelekile (umugqa owodwa). Isihlabathi esingahluziwe sicutshungulwa esihlabathini esiqediwe ngomshini wokomisa kanye nesikrini esidlidlizayo, bese kuba isihlabathi esiqediwe, izinto zikasimende (usimende, i-gypsum, njll.), izithasiselo ezahlukahlukene nezinye izinto ezingavuthiwe ngokuya ngeresiphi ethile, xuba ne-mixer, bese upakisha ngomshini udaka olomile lwempuphu etholwe, kufaka phakathi i-silo yokugcina impahla eluhlaza, i-screw conveyor, isistimu yokubeka isisindo I-hopper exutshwe ngaphambili, i-mixer, umshini wokupakisha, abaqoqi bothuli nohlelo lokulawula.

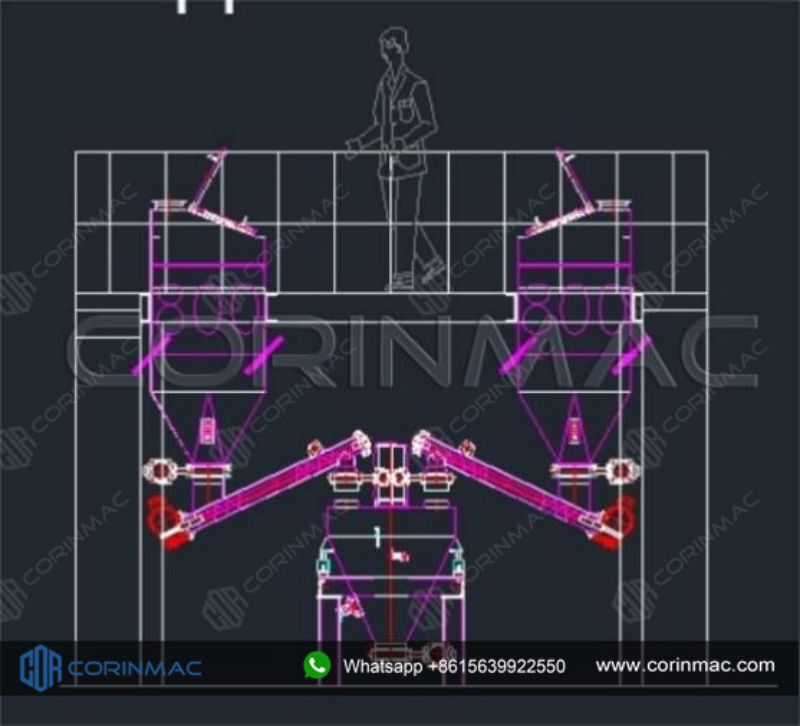

Igama lomugqa wokukhiqiza udaka ome mpo livela esakhiweni sawo esime mpo. I-hopper exutshwe ngaphambili, i-additive batching system, i-mixer kanye nomshini wokupakisha ihlelwe ku-platform yesakhiwo sensimbi ukusuka phezulu kuya phansi, engahlukaniswa ngesakhiwo esisodwa noma esinezitezi eziningi.

Imigqa yokukhiqiza udaka izohluka kakhulu ngenxa yokuhluka kwezidingo zamandla, ukusebenza kobuchwepheshe, ukwakheka kwemishini kanye nezinga lokuzenzakalelayo. Lonke uhlelo lokukhiqiza lungenziwa ngendlela oyifisayo ngokuya ngendawo yekhasimende kanye nesabelomali.

Umugqa wokukhiqiza we-CRL-H uhlanganisa

-Ukomisa nokuhlola ingxenye

•I-sand hopper emanzi

•Isiphakeli sebhande

•Amaconveyor

•Isomisi esijikelezayo

•Isikrini esidlidlizayo

•Umqoqi wothuli kanye nemishini eyiSiza

-Dry mortar production ingxenye

• Amathuluzi okuphakamisa nokudlulisa impahla eluhlaza;

• Impahla yokugcina impahla eluhlaza (silo kanye nesikhwama sokukhulula amathani)

• Isistimu yokuhlanganisa nesisindo (izinto eziyinhloko nezithasiselo)

• Umshini wokuhlanganisa nokupakisha

• Uhlelo Lokulawula

• Izinsizakusebenza

Imininingwane Yomkhiqizo

Ukomisa nokuhlola ingxenye

I-sand hopper emanzi

I-sand hopper emanzi isetshenziselwa ukwamukela nokugcina isihlabathi esimanzi ukuze somiswe. Ivolumu (umthamo ojwayelekile ngu-5T) ungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. I-outlet engezansi kwe-sand hopper ixhunywe kumphakeli webhande. Isakhiwo sihlangene futhi sinengqondo, siqinile futhi sihlala isikhathi eside.

Isihambisi sebhande

I-belt conveyor isetshenziselwa ukuthumela isihlabathi esimanzi ukomisa, futhi idlulisele isihlabathi esomile esikrinini esidlidlizayo noma kunoma iyiphi indawo ekhethiwe. Sisebenzisa ibhande le-nylon conveyor, elinamandla aphezulu, ukumelana nomthelela nokuphila isikhathi eside.

Isiphakeli sebhande

I-feeder yebhande iyisisetshenziswa esibalulekile sokuphakela isihlabathi esimanzi ngokulinganayo kumshini wokomisa, futhi umphumela wokomisa ungaqinisekiswa kuphela ngokuphakela impahla ngokulinganayo. Isiphakeli sifakwe injini elawula isivinini esishintshashintshayo, futhi isivinini sokuphakela singashintshwa ngokuzenzakalelayo ukuze kuzuzwe umphumela wokumisa ongcono kakhulu. Isebenzisa ibhande le-skirt conveyor ukuvimbela ukuvuza kwezinto.

Isomisi esinamasilinda amathathu

Isomisi se-cylinder rotary emithathu siwumkhiqizo ophumelelayo futhi owonga amandla othuthukisiwe ngesisekelo sesomisi esijikelezayo esinesilinda esisodwa.

Kunesakhiwo sesigubhu esinezendlalelo ezintathu kusilinda, esingenza izinto zibuyele kathathu kusilinda, ukuze ikwazi ukuthola ukushintshaniswa kokushisa okwanele, ithuthukise kakhulu izinga lokusetshenziswa kokushisa futhi inciphise ukusetshenziswa kwamandla.

Isikrini esidlidlizayo

Ngemva kokumiswa, isihlabathi esiqediwe (okuqukethwe kwamanzi ngokuvamile kungaphansi kuka-0.5%) singena esikrinini esidlidlizayo, esingahlungwa sibe osayizi abahlukahlukene bezinhlayiyana futhi sikhishwe ezimbobeni zokulahla ezifanele ngokuya ngezidingo. Ngokuvamile, ubukhulu bemeshi yesikrini bungu-0.63mm, 1.2mm kanye no-2.0mm, usayizi othize wemeshi uyakhethwa futhi unqunywe ngokuya ngezidingo zangempela.

Umqoqi wothuli kanye nemishini eyiSiza

Isishingishane

Ixhunywe endaweni yokukhipha umoya yesembozo sokugcina sesomisi ngepayipi, futhi iyithuluzi lokuqala lokususa uthuli legesi eshisayo ephuma phakathi kwesomisi. Kunezinhlobonhlobo zezakhiwo ezifana ne-cyclone eyodwa kanye neqembu le-cyclone eliphindwe kabili elingakhethwa.

Impulse uthuli umqoqi

Kungenye imishini yokususa uthuli emugqeni wokomisa. Isakhiwo sayo sangaphakathi sesikhwama sesihlungi samaqembu amaningi kanye nomklamo wejethi we-pulse kungahlunga kahle futhi kuqoqe uthuli emoyeni ogcwele uthuli, ukuze okuqukethwe kothuli lomoya okhipha umoya okhipha umoya kungabi ngaphansi kuka-50mg/m³, kuqinisekiswe ukuthi kuhlangabezana nezidingo zokuvikela imvelo. Ngokwezidingo, sinenqwaba yamamodeli afana ne-DMC32, DMC64, DMC112 ongawakhetha.

Ingxenye yokukhiqiza udaka olomile

Imishini yokuphakamisa nokudlulisa

Ikheshi lebhakede

I-elevator yebhakede iklanyelwe ukuthutha okuqhubekayo okuqondile kwezinto eziningi ezifana nesihlabathi, amatshe, itshe elichotshoziwe, i-peat, i-slag, amalahle, njll ekukhiqizeni izinto zokwakha, amakhemikhali, i-metallurgical nezinye izimboni.

Isikulufa sokuhambisa

I-screw conveyor ilungele ukuhanjiswa kwezinto ezingezona i-viscous ezifana nempushana eyomile, usimende, njll. Isetshenziselwa ukuthutha impushana eyomile, usimende, i-gypsum powder nezinye izinto zokusetshenziswa ekuhlanganiseni kolayini wokukhiqiza, futhi ithuthe imikhiqizo exubile iye ku-hopper yomkhiqizo ophelile. Ingxenye engezansi ye-screw conveyor enikezwe inkampani yethu ifakwe i-feeding hopper, futhi abasebenzi bafaka izinto zokusetshenziswa ku-hopper. Isikulufu senziwe ngepuleti lensimbi ye-alloy, futhi ukujiya kuhambelana nezinto ezihlukile okufanele zidluliselwe. Zombili iziphetho ze-conveyor shaft zisebenzisa isakhiwo esikhethekile sokuvala ukuze kuncishiswe umthelela wothuli ekuthwaleni.

Impahla yokugcina impahla eluhlaza (silo nesikhwama sethani un-loader)

ISilo sikasimende, isihlabathi, umcako, njll.

I-silo (i-demountable design) iklanyelwe ukwamukela usimende elolini likasimende, iwugcine futhi iwulethe kanye ne-screw conveyor ohlelweni lokuhlanganisa.

Ukulayishwa kukasimende esiseleni kwenziwa ngepayipi likasimende womoya. Ukuze uvimbele ukulengiswa kwempahla nokuqinisekisa ukuthululwa okungaphazanyiswa, isistimu yokungenisa umoya ifakwa engxenyeni engezansi (yekhoni) yesisele.

Isikhwama sethani esingalayishi

Njengokwejwayelekile, i-hopper ifakwe i-breaker yokuklebhula iziqukathi ezithambile zohlobo lwe-"big-bag", i-valve uvemvane eklanyelwe ukuvuleka ngokugcwele, ukuvala nokulawula ukuhamba kwezinto eziyinqwaba kusukela ku-hopper. ngesicelo seklayenti, isidlidlizi se-electromechanical singafakwa ku-hopper ukuze sikhuthaze ukuthululwa kwezinto eziningi.

• Isistimu yokuhlanganisa nesisindo (izinto eziyinhloko nezithasiselo)

Izinto ezisemqoka ezinesisindo se-hopper

I-hopper yokukala iqukethe i-hopper, ifremu yensimbi, kanye neseli yomthwalo (ingxenye engezansi ye-hopper yokukala ifakwe isikulufu sokukhipha). I-hopper yokukala isetshenziswa kakhulu emigqeni yodaka ehlukahlukene ukukala izithako ezifana nosimende, isihlabathi, umlotha wommpukane, i-calcium ekhanyayo, ne-calcium enzima. Inezinzuzo zejubane lokuhlanganisa elisheshayo, ukunemba kokulinganisa okuphezulu, ukuguquguquka okunamandla, futhi ingakwazi ukuphatha izinto eziningi ezahlukene.

I-Additives batching system

I-Mixer kanye nomshini wokupakisha

I-Dry mortar mixer

Umxube wodaka owomile uyisisetshenziswa esiyinhloko somugqa wokukhiqiza udaka olomile, onquma ikhwalithi yodaka. Izixube ezihlukene zodaka zingasetshenziswa ngokwezinhlobo ezahlukene zodaka.

I-Single shaft plough share mixer

Ubuchwepheshe bomxube wokwabelana ngegeja buvela ikakhulukazi eJalimane, futhi buyingxube evame ukusetshenziswa emigqeni emikhulu yokukhiqiza udaka lwempushana eyomile. Isihlanganisi sokwabelana ngegeja ikakhulukazi sakhiwe isilinda sangaphandle, ishafti eyinhloko, izingxenye zegeja, nezibambo zezabelo zegeja. Ukuzungezisa kwe-shaft eyinhloko kushayela izindwani ezifana negeja ukuthi zijikeleze ngesivinini esikhulu ukuze kushayele izinto ezihamba ngokushesha kuzo zombili izinkomba, ukuze kufezwe injongo yokuxuba. Ijubane elishukumisayo liyashesha, futhi ummese endizayo ufakwe odongeni lwesilinda, ongahlakaza ngokushesha izinto, ukuze ukuxuba kufane futhi kusheshe, futhi izinga lokuxuba liphezulu.

I-single shaft plough share mixer (umnyango omncane wokukhipha)

I-single shaft plough share mixer (umnyango omkhulu wokukhipha)

I-Single shaft plough share mixer (Ijubane eliphezulu lesidlo sakusihlwa)

I-hopper yomkhiqizo

I-hopper yomkhiqizo oqediwe iyisilo esivaliwe esenziwe ngamapuleti ensimbi ye-alloy yokugcina imikhiqizo exubile. Ingaphezulu lesilo lifakwe imbobo yokudla, isistimu yokuphefumula kanye nedivayisi yokuqoqa uthuli. Ingxenye yekhoni yesisele ifakwe isidlidlizi somoya kanye nethuluzi lokuphula i-arch ukuvimbela impahla ukuthi ingavinjwa ku-hopper.

Umshini wokupakisha isikhwama se-valve

Ngokwezidingo zamakhasimende ahlukene, singahlinzeka ngezinhlobo ezintathu ezihlukene zomshini wokupakisha, uhlobo lwe-impeller, uhlobo lokushaya umoya kanye nohlobo oluntantayo lomoya ozikhethele lona. I-module yokukala iyingxenye eyinhloko yomshini wokupakisha isikhwama se-valve. Inzwa yokukala, isilawuli sesisindo kanye nezingxenye zokulawula i-elekthronikhi ezisetshenziswa emshinini wethu wokupakisha zonke ziyizimpawu zesigaba sokuqala, ezinobubanzi obukhulu bokulinganisa, ukunemba okuphezulu, impendulo ebucayi, kanye nephutha lesisindo kungaba ± 0.2 %, lingahlangabezana ngokugcwele nezidingo zakho.

Ikhabhinethi yokulawula

Izinto zokusebenza ezibalwe ngenhla ziwuhlobo oluyisisekelo lwalolu hlobo lomugqa wokukhiqiza.

Uma kudingekile ukunciphisa uthuli emsebenzini futhi uthuthukise indawo yokusebenza yabasebenzi, umqoqi omncane wothuli we-pulse angafakwa.

Ngamafuphi, singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho.

1 kuya ku-1 isevisi eyenziwe ngokwezifiso

Singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho. Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nesakhiwo semishini yokukhiqiza.

Ububanzi besicelo

Iphrojekthi Eyimpumelelo

Sinezingosi ezinezihloko eziningi emazweni angaphezu kwama-40 emhlabeni jikelele. Ingxenye yezingosi zethu zokufaka zimi kanje:

Iphrofayela Yenkampani

I-CORINMAC-Cooperation&Win-Win, lona umsuka wegama leqembu lethu.

Lesi futhi isimiso sethu sokusebenza: ngokusebenzisana ngokubambisana nokubambisana namakhasimende, dala inani labantu ngabanye kanye namakhasimende, bese siqaphela ukubaluleka kwenkampani yethu.

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeleni amakhasimende ethu izixazululo ezingcono kakhulu ngokunikeza amathuluzi ekhwalithi ephezulu kanye nemigqa yokukhiqiza yezinga eliphezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yekhasimende impumelelo yethu!

Ukuvakasha kwamakhasimende

Siyakwamukela ku-CORINMAC. Ithimba lochwepheshe le-CORINMAC likunikeza amasevisi aphelele. Kungakhathaliseki ukuthi uvela kuliphi izwe, singakunikeza ukwesekwa okucabangela kakhulu. Sinolwazi oluningi ezitshalweni zokukhiqiza udaka olomile. Sizokwabelana ngolwazi lwethu namakhasimende ethu futhi siwasize aqale amabhizinisi awo futhi enze imali. Sibonga amakhasimende ethu ngokusethemba nokusisekela!

Ukupakishwa kokuthunyelwa

I-CORINMAC inabalingani abangochwepheshe bezokuthutha kanye nezokuhamba abaye babambisana iminyaka engaphezu kwe-10, behlinzeka ngezinsizakalo zokulethwa kwemishini yendlu ngendlu.

Impendulo yomsebenzisi

Imikhiqizo yethu izuze idumela elihle nokuqashelwa emazweni angaphezu kuka-40, okuhlanganisa i-United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, njll.

Ukufakwa kanye nokugunyazwa

I-CORINMAC ihlinzeka ngezinsizakalo zokufakwa esizeni kanye nezokuthuma. Singathumela onjiniyela abangochwepheshe kusayithi lakho ngokuya ngezidingo zakho futhi siqeqeshe abasebenzi abasesiza ukuthi basebenzise imishini. Futhi singahlinzeka ngezinsizakalo zokuqondisa ukufakwa kwevidiyo.

Isiqondiso sezinyathelo zokufaka

Umdwebo

Izitifiketi

Sisebenza ngokukhethekile ekuklanyeni, ekukhiqizeni nasekunikezeni imikhiqizo elandelayo:

Ulayini wokukhiqiza udaka olomile

Kubandakanya ulayini wokukhiqiza we-Tile adhesive, ulayini wokukhiqiza we-Wall putty, ulayini wokukhiqiza ijazi le-Skim, ulayini wokukhiqiza udaka olusekelwe kusimende, ulayini wokukhiqiza udaka olusekelwe eGypsum, kanye nezinhlobo ezahlukene zesethi yodaka olomile oluphelele. Uhlu lomkhiqizo luhlanganisa i-silo ye-Raw material storage, i-Batching & Weighing system, ama-Mixers, umshini wokupakisha (Umshini wokugcwalisa), i-robot ye-Palletizing kanye nezinhlelo zokulawula okuzenzakalelayo ze-PLC.

Imishini yokukhiqiza impahla yodaka eyomile

Kubandakanya umshini wokomisa iRotary, ulayini wokukhiqiza okomisa isihlabathi, Umshini wokugaya, ulayini wokugaya we-produciton wokulungiselela i-gypsum, i-limestone, i-lime, imabula nezinye izimpushana zamatshe.

Yini esingakwenzela yona?

Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nezakhiwo zemishini yokukhiqiza. Sinezindawo eziningi zamacala emazweni angaphezu kwama-40 emhlabeni jikelele. Izixazululo ezenzelwe wena zizovumelana nezimo futhi zisebenze kahle, futhi ngokuqinisekile uzothola izixazululo ezifanele kakhulu zokukhiqiza ezivela kithi!

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeni izixazululo ezingcono kakhulu zamakhasimende ethu, ukuhlinzeka ngemishini yekhwalithi ephezulu kanye nemigqa yokukhiqiza ephezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yamakhasimende impumelelo yethu!

Imikhiqizo yethu

Imikhiqizo enconyiwe

Ukusebenza okuzinzile namandla amakhulu okudlulisa b...

I-Bucket lifti iyisisetshenziswa esisetshenziswa kakhulu sokudlulisa mpo. Isetshenziselwa ukuthutha okuqondile kwempushana, i-granular kanye nezinto eziyinqwaba, kanye nezinto ezilumayo kakhulu, ezifana usimende, isihlabathi, amalahle enhlabathi, isihlabathi, njll. Izinga lokushisa lempahla ngokuvamile lingaphansi kuka-250 °C, futhi ukuphakama kokuphakamisa kungafinyelela amamitha angu-50.

Umthamo wokudlulisa: 10-450m³/h

Ububanzi bokusebenza: futhi isetshenziswa kabanzi ezintweni zokwakha, amandla kagesi, i-metallurgy, imishini, imboni yamakhemikhali, izimayini nezinye izimboni.

Buka Okuningi

Umugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-2

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka Okuningi

Umugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-3

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka Okuningi

Isisele seshidi elihlukanisekayo futhi elizinzile

Izici:

1. Ububanzi bomzimba wesisele bungaklanywa ngokungenasisekelo ngokwezidingo.

2. Umthamo omkhulu wokugcina, ngokuvamile amathani ayi-100-500.

3. Umzimba wesisele ungahlakazwa ukuze uhanjiswe futhi uhlanganiswe esizeni. Izindleko zokuthumela zehliswa kakhulu, futhi isitsha esisodwa singabamba ama-silo amaningi.

Buka Okuningi

Isiphakeli sebhande esiqinile nesisebenza kahle

Izici:

I-feeder yebhande ifakwe injini elawula isivinini esishintshashintshayo, futhi isivinini sokuphakela singashintshwa ngokuzenzakalelayo ukuze kuzuzwe umphumela wokomisa ongcono kakhulu wezinye izidingo.

Isebenzisa ibhande le-skirt conveyor ukuvimbela ukuvuza kwezinto.

Buka Okuningi

I-Rotary dryer esebenzisa amandla aphansi futhi hi...

Izici Nezinzuzo:

1. Ngokusho kwezinto ezihlukene okufanele zomiswe, isakhiwo se-cylinder esijikelezayo singakhethwa.

2. Ukusebenza okushelelayo nokuthembekile.

3. Imithombo yokushisa ehlukene iyatholakala: igesi yemvelo, idizili, amalahle, izinhlayiya ze-biomass, njll.

4. Ukulawula izinga lokushisa okuhlakaniphile.