Ulayini wokukhiqiza udaka olomile olula CRM1

Imininingwane Yomkhiqizo

Isingeniso

Ulayini wokukhiqiza udaka olomile olula CRM1

Ulayini wokukhiqiza olula we-CRM1 ulungele ukukhiqizwa kodaka olomile, i-putty powder, udaka lokuplasta, ijazi le-skim kanye neminye imikhiqizo yempushana. Isethi yonke yemishini ilula futhi iyasebenza, inomlando omncane, ukutshalwa kwezimali okuphansi kanye nezindleko zokunakekela eziphansi. Kuyisinqumo esifanelekile sezitshalo ezincane zokucubungula udaka olomile.

Ukucushwa kungokulandelayo

Isikulufa sokuhambisa

I-screw conveyor ilungele ukuhanjiswa kwezinto ezingezona i-viscous ezifana nempushana eyomile, usimende, njll. Isetshenziselwa ukuthutha impushana eyomile, usimende, i-gypsum powder nezinye izinto zokusetshenziswa ekuhlanganiseni kolayini wokukhiqiza, futhi ithuthe imikhiqizo exubile iye ku-hopper yomkhiqizo ophelile. Ingxenye engezansi ye-screw conveyor enikezwe inkampani yethu ifakwe i-feeding hopper, futhi abasebenzi bafaka izinto zokusetshenziswa ku-hopper. Isikulufu senziwe ngepuleti lensimbi ye-alloy, futhi ukujiya kuhambelana nezinto ezihlukile okufanele zidluliselwe. Zombili iziphetho ze-conveyor shaft zisebenzisa isakhiwo esikhethekile sokuvala ukuze kuncishiswe umthelela wothuli ekuthwaleni.

I-Spiral ribbon mixer

I-Spiral ribbon mixer inesakhiwo esilula, ukusebenza kahle kokuxuba, ukusetshenziswa kwamandla okuphansi, izinga elikhulu lokugcwalisa umthwalo (ngokuvamile i-40% -70% yevolumu ye-mixer tank), ukusebenza okulula nokugcinwa, futhi ifanele ukuxuba izinto ezimbili noma ezintathu. Ukuze sithuthukise umphumela wokuxuba futhi sifinyeze isikhathi sokuxuba, siklame isakhiwo seribhoni sezendlalelo ezintathu eziphambili; indawo ephambanayo, isikhala kanye nemvume phakathi kweribhoni ne-mixer tank yangaphakathi yangaphakathi yakhelwe ngokuya ngezinto ezahlukahlukene. Ngaphezu kwalokho, ngokwezimo zokusebenza ezahlukene, imbobo yokukhipha mixer ingafakwa i-butterfly valve manual noma i-pneumatic butterfly valve.

I-hopper yomkhiqizo eqediwe

I-hopper yomkhiqizo oqediwe iyi-hopper evaliwe eyenziwe ngamapuleti ensimbi ye-alloy yokugcina imikhiqizo exubile. Ingaphezulu le-hopper ifakwe imbobo yokudla, isistimu yokuphefumula kanye nedivayisi yokuqoqa uthuli. Ingxenye yekhoni ye-hopper ifakwe isidlidlizi somoya kanye nedivaysi yokuphula i-arch ukuvimbela okokusebenza ukuthi kungavinjwa ku-hopper.

Umshini wokupakisha isikhwama se-valve

Ngokwezidingo zamakhasimende ahlukene, singahlinzeka ngezinhlobo ezintathu ezihlukene zomshini wokupakisha, uhlobo lwe-impeller, uhlobo lokushaya umoya kanye nohlobo oluntantayo lomoya ozikhethele lona. I-module yokukala iyingxenye eyinhloko yomshini wokupakisha isikhwama se-valve. Inzwa yokukala, isilawuli sesisindo kanye nezingxenye zokulawula i-elekthronikhi ezisetshenziswa emshinini wethu wokupakisha zonke ziyizimpawu zesigaba sokuqala, ezinobubanzi obukhulu bokulinganisa, ukunemba okuphezulu, impendulo ebucayi, kanye nephutha lesisindo kungaba ± 0.2 %, lingahlangabezana ngokugcwele nezidingo zakho.

Ikhabhinethi yokulawula

Izinto zokusebenza ezibalwe ngenhla wukucushwa okuyisisekelo kwalolu hlobo lomugqa wokukhiqiza. Uma ufuna ukubona umsebenzi we-batching othomathikhi yezinto zokusetshenziswa, i-batching eneweight hopper ingangezwa emgqeni wokukhiqiza. Uma kudingeka ukunciphisa uthuli emsebenzini futhi kuthuthukiswe indawo yokusebenza yabasebenzi, kungafakwa umqoqi omncane wothuli lwe-pulse. Ngamafuphi, singenza imiklamo ehlukene yephrojekthi kanye nokucushwa ngokwezidingo zakho.

Ububanzi besicelo

Umugqa wokukhiqiza olula ulungele ukukhiqizwa kodaka olomile, i-putty powder, i-plastering mortar, i-skim coat neminye imikhiqizo yempushana. Isethi yonke yemishini ilula futhi iyasebenza, inomlando omncane, ukutshalwa kwezimali okuphansi kanye nezindleko zokunakekela eziphansi. Kuyisinqumo esifanelekile sezitshalo ezincane zokucubungula udaka olomile.

1 kuya ku-1 isevisi eyenziwe ngokwezifiso

Singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho. Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nesakhiwo semishini yokukhiqiza.

Iphrofayela Yenkampani

I-CORINMAC-Cooperation&Win-Win, lona umsuka wegama leqembu lethu.

Lesi futhi isimiso sethu sokusebenza: ngokusebenzisana ngokubambisana nokubambisana namakhasimende, dala inani labantu ngabanye kanye namakhasimende, bese siqaphela ukubaluleka kwenkampani yethu.

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeleni amakhasimende ethu izixazululo ezingcono kakhulu ngokunikeza amathuluzi ekhwalithi ephezulu kanye nemigqa yokukhiqiza yezinga eliphezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yekhasimende impumelelo yethu.

Ukuvakasha kwamakhasimende

Siyakwamukela ku-CORINMAC. Ithimba lochwepheshe le-CORINMAC likunikeza amasevisi aphelele. Kungakhathaliseki ukuthi uvela kuliphi izwe, singakunikeza ukwesekwa okucabangela kakhulu. Sinolwazi oluningi ezitshalweni zokukhiqiza udaka olomile. Sizokwabelana ngolwazi lwethu namakhasimende ethu futhi siwasize aqale amabhizinisi awo futhi enze imali. Sibonga amakhasimende ethu ngokusethemba nokuseseka.

Impendulo yomsebenzisi

Imikhiqizo yethu izuze idumela elihle nokuqashelwa emazweni angaphezu kuka-40, okuhlanganisa i-United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, njll.

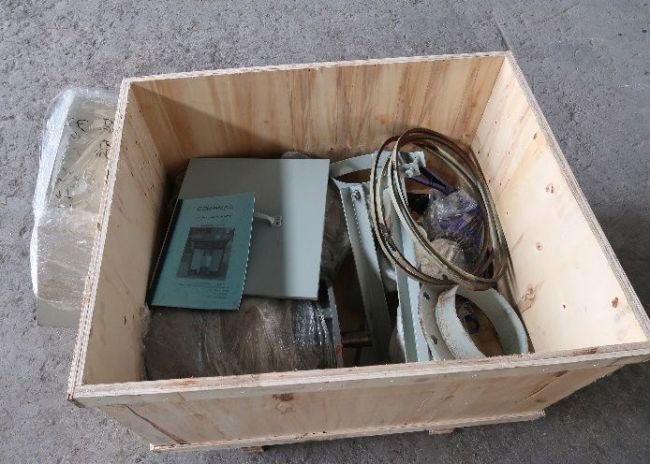

Ukufakwa kanye nokugunyazwa

I-CORINMAC ihlinzeka ngezinsizakalo zokufakwa esizeni kanye nezokuthuma. Singathumela onjiniyela abangochwepheshe kusayithi lakho ngokuya ngezidingo zakho futhi siqeqeshe abasebenzi abasesiza ukuthi basebenzise imishini. Futhi singahlinzeka ngezinsizakalo zokuqondisa ukufakwa kwevidiyo.

Umdwebo

Imikhiqizo yethu

Imikhiqizo enconyiwe

Ulayini wokukhiqiza udaka olomile olula CRM2

Amandla:1-3TPH; 3-5TPH; 5-10TPH

Izici Nezinzuzo:

1. Isakhiwo esihlangene, umkhondo omncane.

2. Ifakwe umshini wokuthulula izikhwama zamathani ukuze icubungule izinto ezingavuthiwe futhi yehlise izinga lomsebenzi wabasebenzi.

3. Sebenzisa i-hopper yokukala ukuze uhlanganise ngokuzenzakalelayo izithako ukuze uthuthukise ukusebenza kahle kokukhiqiza.

4. Wonke umugqa ungabona ukulawula okuzenzakalelayo.

Ulayini wokukhiqiza udaka olomile olula CRM3

Amandla:1-3TPH; 3-5TPH; 5-10TPH

Izici Nezinzuzo:

1. Izixube eziphindwe kabili zisebenza ngesikhathi esifanayo, ziphinda kabili okukhiphayo.

2. Izinhlobonhlobo zemishini yokugcina impahla eluhlaza uyazikhethela, njengokuthulula isikhwama sethani, i-sand hopper, njll., elula futhi eguquguqukayo ukuyilungisa.

3. Ukukala okuzenzakalelayo nokuxutshwa kwezithako.

4. Wonke ulayini ungabona ukulawula okuzenzakalelayo futhi unciphise izindleko zabasebenzi.

Umugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-1

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka OkuningiUmugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-2

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka OkuningiUmugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-3

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka OkuningiUlayini wokukhiqiza udaka olomile ome mpo lwe-CRL-H

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka OkuningiUmugqa wokukhiqiza udaka olomile ome mpo lwe-CRL-HS

Amandla:5-10TPH; 10-15TPH; 15-20TPH

Buka OkuningiUhlobo lombhoshongo umugqa wokukhiqiza udaka olomile

Amandla:10-15TPH; 15-20TPH; 20-30TPH; 30-40TPH; 50-60TPH

Izici Nezinzuzo:

1. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle kokukhiqiza okuphezulu.

2. Ukumosha okuncane kwezinto zokusetshenziswa, akukho ukungcoliswa kwezintuli, nezinga eliphansi lokwehluleka.

3. Futhi ngenxa yesakhiwo sezisele zempahla eluhlaza, umugqa wokukhiqiza uthatha indawo engu-1/3 yomugqa wokukhiqiza oyisicaba.