Ukomisa umugqa wokukhiqiza osebenzisa amandla aphansi kanye nokuphuma okuphezulu

Imininingwane Yomkhiqizo

Ukomisa umugqa wokukhiqiza

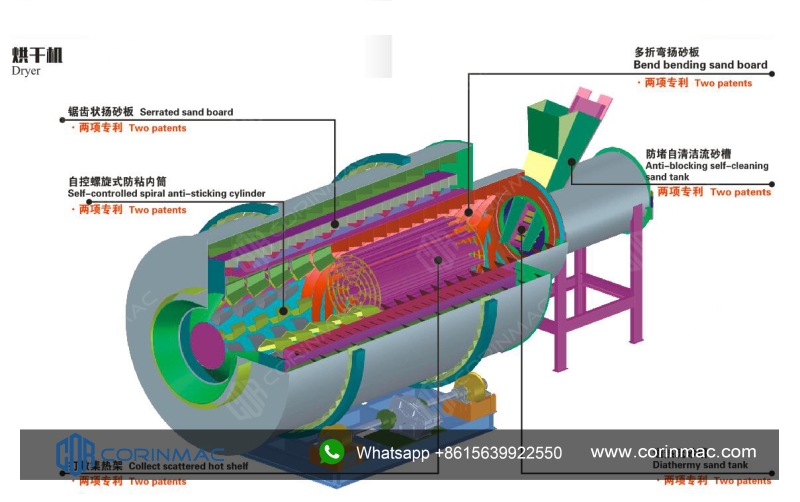

Umugqa wokukhiqiza okomisa isethi ephelele yemishini yokomisa ukushisa nokuhlola isihlabathi noma ezinye izinto eziningi. Iqukethe izingxenye ezilandelayo: i-sand hopper emanzi, i-feeder yebhande, i-conveyor yebhande, ikamelo elivuthayo, isomisi esijikelezayo (isomisi esinamasilinda amathathu, isomisi esinamasilinda owodwa), isishingishane, isiqoqi sothuli olushaywayo, isiphephelo sefeni, isikrini esidlidlizayo, nohlelo lokulawula ngogesi.

Isihlabathi sifakwa ku-santi hopper emanzi ngesilayishi, futhi sidluliselwe endaweni yokomisa nge-feed yebhande kanye ne-conveyor, bese singena endaweni yokomisa ejikelezayo. I-burner ihlinzeka ngomthombo wokushisa okomisa, futhi isihlabathi esomile sithunyelwa esikrinini esidlidlizayo isithumeli sebhande ukuze sihlolwe (imvamisa usayizi wemeshi ungu-0.63, 1.2 no-2.0mm, usayizi othize wemeshi uyakhethwa futhi unqunywa ngokuya ngezidingo zangempela). Ngesikhathi senqubo yokomisa, isiphephetha-moya esisalungiswa, isivunguvungu, isiqoqi sothuli lwe-pulse kanye nepayipi bakha uhlelo lokususa uthuli lomugqa wokukhiqiza, futhi wonke umugqa uhlanzekile futhi ucocekile!

Ngenxa yokuthi isihlabathi siyinto esetshenziswa kakhulu eluhlaza odakeni olomile, ulayini wokukhiqiza owomile uvame ukusetshenziswa ngokuhambisana nolayini wokukhiqiza udaka olomile.

Ukwakhiwa komugqa wokukhiqiza

I-sand hopper emanzi

I-sand hopper emanzi isetshenziselwa ukwamukela nokugcina isihlabathi esimanzi ukuze somiswe. Ivolumu (umthamo ojwayelekile ngu-5T) ungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi. I-outlet engezansi kwe-sand hopper ixhunywe kumphakeli webhande. Isakhiwo sihlangene futhi sinengqondo, siqinile futhi sihlala isikhathi eside.

Isiphakeli sebhande

I-feeder yebhande iyisisetshenziswa esibalulekile sokuphakela isihlabathi esimanzi ngokulinganayo kumshini wokomisa, futhi umphumela wokomisa ungaqinisekiswa kuphela ngokuphakela impahla ngokulinganayo. Isiphakeli sifakwe injini elawula isivinini esishintshashintshayo, futhi isivinini sokuphakela singashintshwa ngokuzenzakalelayo ukuze kuzuzwe umphumela wokumisa ongcono kakhulu. Isebenzisa ibhande le-skirt conveyor ukuvimbela ukuvuza kwezinto.

Isihambisi sebhande

I-belt conveyor isetshenziselwa ukuthumela isihlabathi esimanzi ukomisa, futhi idlulisele isihlabathi esomile esikrinini esidlidlizayo noma kunoma iyiphi indawo ekhethiwe. Sisebenzisa ibhande le-nylon conveyor, elinamandla aphezulu, ukumelana nomthelela nokuphila isikhathi eside.

Igumbi elivuthayo

Nikeza isikhala sokushiswa kukaphethiloli, ukuphela kwegumbi kuhlinzekwa nge-inlet yomoya kanye ne-valve yokulawula umoya, futhi ingaphakathi lakhiwe ngosimende nezitini eziphikisayo, futhi izinga lokushisa ekamelweni elivuthayo lingafinyelela ku-1200 ℃. Isakhiwo sayo sihle futhi sinengqondo, futhi sihlanganiswe eduze nesilinda esomisile ukunikeza umthombo wokushisa owanele wesomisi.

Isomisi esinamasilinda amathathu

Isomisi se-cylinder rotary emithathu siwumkhiqizo ophumelelayo futhi owonga amandla othuthukisiwe ngesisekelo sesomisi esijikelezayo esinesilinda esisodwa.

Kunesakhiwo sesigubhu esinezendlalelo ezintathu kusilinda, esingenza izinto zibuyele kathathu kusilinda, ukuze ikwazi ukuthola ukushintshaniswa kokushisa okwanele, ithuthukise kakhulu izinga lokusetshenziswa kokushisa futhi inciphise ukusetshenziswa kwamandla.

Isimiso sokusebenza

Impahla ingena esigubhu sangaphakathi esomisile isuka kudivayisi yokuphakela ukuze ibone ukomiswa komfula. Okubalulekile kuphakanyiswa ngokuqhubekayo futhi kusakazwe ipuleti eliphakamisayo elingaphakathi futhi lihamba ngendlela ezungezayo ukuze libone ukushintshana kokushisa, kuyilapho okokusebenza kuya komunye umkhawulo wesigubhu sangaphakathi bese kungena kusigubhu esimaphakathi, futhi okubalulekile kuphakanyiswa ngokuqhubekayo nokuphindaphindiwe esigubhu esimaphakathi, ngendlela yezinyathelo ezimbili ukuya phambili nesinyathelo esisodwa emuva, okubalulekile kukhishwa ngaphakathi komgqomo futhi kumunca ukushisa kwangaphakathi. ukushisa kwesigubhu esiphakathi ngesikhathi esifanayo, isikhathi sokumisa sihlala isikhathi eside, futhi impahla ifinyelela esimweni esihle kakhulu sokumisa ngalesi sikhathi. Impahla iya komunye umkhawulo wesigubhu esiphakathi bese iwela esigubhu sangaphandle. Impahla ihamba ngendlela engunxande enamaluphu amaningi esigubhuni sangaphandle. Izinto ezifeza umphumela wokomisa zihamba ngokushesha futhi zikhiphe isigubhu ngaphansi kwesenzo somoya oshisayo, futhi izinto ezimanzi ezingakafinyeleli umphumela wokomisa azikwazi ukuhamba ngokushesha ngenxa yesisindo sazo, futhi izinto zomiswe ngokugcwele kulezi zingcwecwe zokuphakamisa unxande, ngaleyo ndlela zigcwalise inhloso yokomisa.

Izinzuzo

1. Isakhiwo se-cylinder emithathu yesigubhu sokumisa sandisa indawo yokuxhumana phakathi kwezinto ezimanzi nomoya oshisayo, okunciphisa isikhathi sokumisa ngo-48-80% uma kuqhathaniswa nesisombululo sendabuko, futhi izinga lokukhuphuka komswakama lingafinyelela ku-120-180 kg / m3, futhi ukusetshenziswa kukaphethiloli kuncishiswe ngo-48-80%. Ukusetshenziswa 6-8 kg/ton.

2. Ukomiswa kwezinto akwenziwa kuphela ngokugeleza komoya oshisayo, kodwa futhi kwenziwa ngemisebe ye-infrared yensimbi evuthayo ngaphakathi, okuthuthukisa izinga lokusebenzisa ukushisa kwesomiso sonke.

3. Usayizi ophelele wesomiso wehliswa ngaphezu kuka-30% uma kuqhathaniswa nezomisi ezijwayelekile ezinesilinda esisodwa, ngaleyo ndlela kunciphisa ukulahlekelwa ukushisa kwangaphandle.

4. Ukusebenza kahle kokushisa kwe-self-insulating dryer kuphezulu njengo-80% (uma kuqhathaniswa no-35% kuphela wesomiso esijwayelekile esijikelezayo), kanti ukusebenza kahle kokushisa kuphezulu ngo-45%.

5. Ngenxa yokufakwa okuhlangene, indawo yaphansi iyancipha ngo-50% futhi izindleko zengqalasizinda zehliswa ngo-60%.

6. Izinga lokushisa lomkhiqizo oqediwe ngemva kokumisa lingaba ngama-degree angu-60-70, ukuze lingadingi i-cooler eyengeziwe yokupholisa.

7. Izinga lokushisa lokukhipha umoya liphansi, futhi ukuphila kwesikhwama sokuhlunga uthuli kwandiswa izikhathi ezingu-2.

8. Umswakama wokugcina oyifunayo ungalungiswa kalula ngokuya ngezidingo zomsebenzisi.

Imingcele yomkhiqizo

| Imodeli | Isilinda esingaphandle.(м) | Ubude besilinda sangaphandle (м) | Isivinini esiphendukayo (r/min) | Ivolumu (m³) | Amandla okomisa (t/h) | Amandla (kw) |

| HG1520 | 1.5 | 2 | 3-10 | 3.5 | 3-5 | 5.5 |

| HG2240 | 2 | 4 | 3-10 | 9 | 8-15 | 7.5 |

| HG2550 | 2.2 | 5 | 3-10 | 15.7 | 15-20 | 2*5.5 |

| HG2958 | 2.6 | 5.8 | 3-10 | 33 | 30-35 | 4*5.5 |

| HG3270 | 2.9 | 7 | 3-10 | 41 | 50-60 | 4*11 |

| HG3890 | 3.4 | 9 | 3-10 | 68 | 80-90 | 4*11 |

Qaphela:

1. Le mingcele ibalwa ngokusekelwe kokuqukethwe komswakama wesihlabathi sokuqala: 10-15%, futhi umswakama ngemva kokumisa ungaphansi kuka-1%. .

2. Izinga lokushisa ekungeneni kwesomisi lingama-650-750 degrees.

3. Ubude nobubanzi besomisi kungashintshwa ngokuvumelana nezidingo zamakhasimende.

Impulse uthuli umqoqi

Kungenye imishini yokususa uthuli emugqeni wokomisa. Isakhiwo sayo sangaphakathi sesikhwama sesihlungi samaqembu amaningi kanye nomklamo wejethi we-pulse kungahlunga kahle futhi kuqoqe uthuli emoyeni ogcwele uthuli, ukuze okuqukethwe kothuli lomoya okhipha umoya okhipha umoya kungabi ngaphansi kuka-50mg/m³, kuqinisekiswe ukuthi kuhlangabezana nezidingo zokuvikela imvelo. Ngokwezidingo, sinenqwaba yamamodeli afana ne-DMC32, DMC64, DMC112 ongawakhetha.

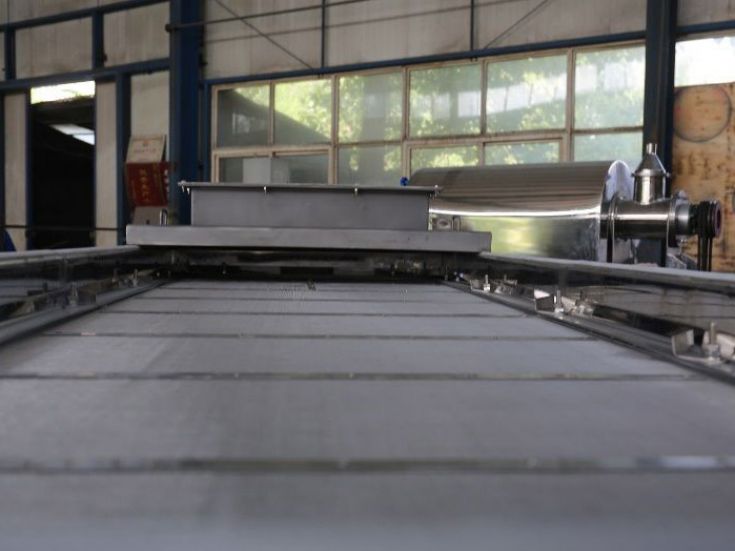

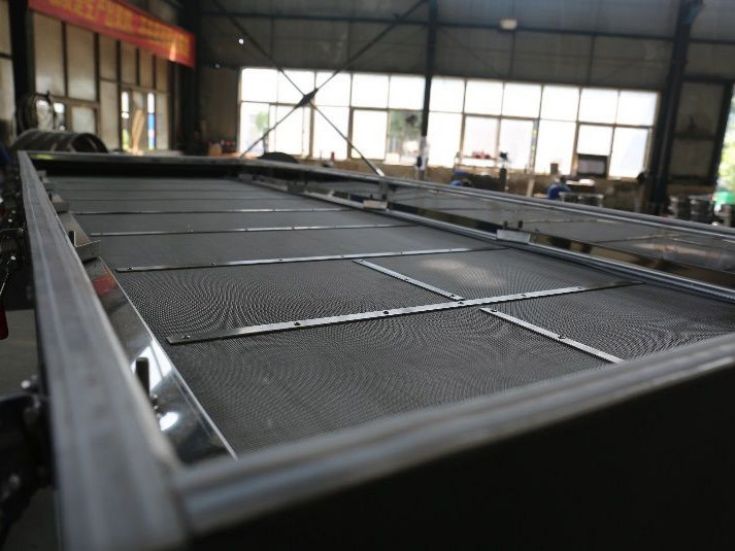

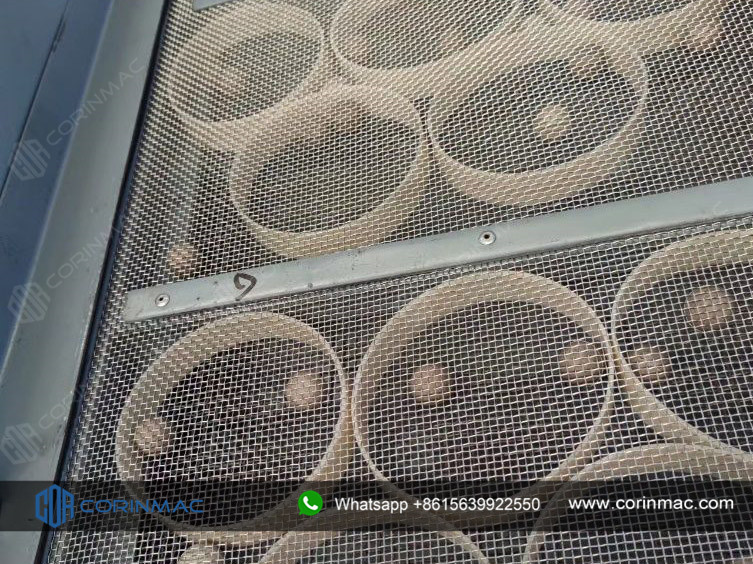

Isikrini esidlidlizayo

Ngemva kokumiswa, isihlabathi esiqediwe (okuqukethwe kwamanzi ngokuvamile kungaphansi kuka-0.5%) singena esikrinini esidlidlizayo, esingahlungwa sibe osayizi abahlukahlukene bezinhlayiyana futhi sikhishwe ezimbobeni zokulahla ezifanele ngokuya ngezidingo. Ngokuvamile, ubukhulu bemeshi yesikrini bungu-0.63mm, 1.2mm kanye no-2.0mm, usayizi othize wemeshi uyakhethwa futhi unqunywe ngokuya ngezidingo zangempela.

Lonke uhlaka lwesikrini sensimbi, ubuchwepheshe bokuqinisa isikrini obuhlukile, kulula ukufaka esikhundleni sesikrini.

Iqukethe amabhola erabha anwebekayo, angasula ngokuzenzakalelayo ukuvinjwa kwesikrini

Izimbambo eziningi eziqinisayo, ziqine kakhulu futhi zithembekile

Uhlelo lokulawula ngogesi

Wonke ulayini wokukhiqiza ulawulwa ngendlela edidiyelwe, ene-interface yokusebenza ebonakalayo, ngokuguqulwa kwemvamisa ukulungisa isivinini sokuphakelayo kanye nokuzungeza kwesigubhu okomisa, ukulawula isishisi ngobuhlakani, nokubona ukulawulwa kwezinga lokushisa okuhlakaniphile neminye imisebenzi.

1 kuya ku-1 isevisi eyenziwe ngokwezifiso

Singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho. Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nesakhiwo semishini yokukhiqiza.

Ububanzi besicelo

Iphrojekthi Eyimpumelelo

Sinezingosi ezinezihloko eziningi emazweni angaphezu kwama-40 emhlabeni jikelele. Ingxenye yezingosi zethu zokufaka zimi kanje:

Ipharamitha yezobuchwepheshe yesitshalo sokukhiqiza isihlabathi esomisa isihlabathi

| Uhlu lwezisetshenziswa | Umthamo (Umswakama ubalwa ngokuvumelana no-5-8%) | |||||

| 3-5TPH | 8-10 TPH | 10-15 TPH | 20-25 TPH | 25-30 TPH | 40-50 TPH | |

| I-sand hopper emanzi | 5T | 5T | 5T | 10T | 10T | 10T |

| Isiphakeli sebhande | PG500 | PG500 | PG500 | Ф500 | Ф500 | Ф500 |

| Isihambisi sebhande | В500х6 | В500х8 | В500х8 | В500х10 | В500х10 | В500х15 |

| Isomisi esinamasilinda amathathu | I-CRH6205 | I-CRH6210 | I-CRH6215 | I-CRH6220 | I-CRH6230 | CRH6250 |

| Igumbi elivuthayo | Ukusekela (kuhlanganise nezitini eziphikisayo) | |||||

| I-Burner (Igesi / Udizili) Amandla ashisayo | I-RS/RL 44T.C 450-600kw | I-RS/RL 130T.C 1000-1500 kw | I-RS/RL 190T.C 1500-2400 kw | I-RS/RL 250T.C 2500-2800 kw | I-RS/RL 310T.C 2800-3500 kw | I-RS/RL 510T.C 4500-5500 kw |

| Isihambisi sebhande lomkhiqizo | В500х6 | В500х6 | В500х6 | В500х8 | В500х10 | В500х10 |

| Isikrini esidlidlizayo (Khetha isikrini ngokuya ngosayizi wezinhlayiyana zomkhiqizo oqediwe) | I-DZS1025 | I-DZS1230 | I-DZS1230 | I-DZS1540 | I-DZS1230 (2台) | I-DZS1530 (2sets) |

| Isihambisi sebhande | В500х6 | В500х6 | В500х6 | В500х6 | В500х6 | В500х6 |

| Isishingishane | Φ500mm | Φ1200 mm | Φ1200 mm | Φ1200 | Φ1400 | Φ1400 |

| Ifeni esalungiswa | Y5-47-5C (5.5kw) | I-Y5-47-5C (7.5KW) | Y5-48-5C (11kw) | Y5-48-5C (11kw) | Y5-48-6.3C 22kvt | Y5-48-6.3C 22kvt |

| Umqoqi wothuli we-Pulse |

|

|

|

|

| |

Iphrofayela Yenkampani

I-CORINMAC-Cooperation&Win-Win, lona umsuka wegama leqembu lethu.

Lesi futhi isimiso sethu sokusebenza: ngokusebenzisana ngokubambisana nokubambisana namakhasimende, dala inani labantu ngabanye kanye namakhasimende, bese siqaphela ukubaluleka kwenkampani yethu.

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeleni amakhasimende ethu izixazululo ezingcono kakhulu ngokunikeza amathuluzi ekhwalithi ephezulu kanye nemigqa yokukhiqiza yezinga eliphezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yekhasimende impumelelo yethu!

Ukuvakasha kwamakhasimende

Siyakwamukela ku-CORINMAC. Ithimba lochwepheshe le-CORINMAC likunikeza amasevisi aphelele. Kungakhathaliseki ukuthi uvela kuliphi izwe, singakunikeza ukwesekwa okucabangela kakhulu. Sinolwazi oluningi ezitshalweni zokukhiqiza udaka olomile. Sizokwabelana ngolwazi lwethu namakhasimende ethu futhi siwasize aqale amabhizinisi awo futhi enze imali. Sibonga amakhasimende ethu ngokusethemba nokusisekela!

Impendulo yekhasimende

Imikhiqizo yethu izuze idumela elihle nokuqashelwa emazweni angaphezu kuka-40, okuhlanganisa i-United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, njll.

Ukufakwa kanye nokugunyazwa

I-CORINMAC ihlinzeka ngezinsizakalo zokufakwa esizeni kanye nezokuthuma. Singathumela onjiniyela abangochwepheshe kusayithi lakho ngokuya ngezidingo zakho futhi siqeqeshe abasebenzi abasesiza ukuthi basebenzise imishini. Futhi singahlinzeka ngezinsizakalo zokuqondisa ukufakwa kwevidiyo.

Umdwebo

Imikhiqizo yethu

Imikhiqizo enconyiwe

Isomisi se-cylinder rotary esinokushisa okuphezulu...

Izici:

1. Usayizi ophelele wesomiso wehliswa ngaphezu kuka-30% uma kuqhathaniswa nezomisi ezijikelezayo ezinesilinda esisodwa, ngaleyo ndlela kunciphisa ukulahlekelwa ukushisa kwangaphandle.

2. Ukusebenza kahle okushisayo kwesomiso esizivikelayo kuphezulu njengo-80% (uma kuqhathaniswa no-35% kuphela wesomiso esijwayelekile esijikelezayo), kanti ukusebenza kahle kokushisa kuphezulu ngo-45%.

3. Ngenxa yokufakwa okuhlangene, indawo yaphansi iyancipha ngo-50%, futhi izindleko zengqalasizinda zehliswa ngo-60%.

4. Izinga lokushisa lomkhiqizo oqediwe ngemva kokumisa lingaba ngama-degree angu-60-70, ukuze lingadingi i-cooler eyengeziwe yokupholisa.

I-Rotary dryer esebenzisa amandla aphansi futhi hi...

Izici Nezinzuzo:

1. Ngokusho kwezinto ezihlukene okufanele zomiswe, isakhiwo se-cylinder esijikelezayo singakhethwa.

2. Ukusebenza okushelelayo nokuthembekile.

3. Imithombo yokushisa ehlukene iyatholakala: igesi yemvelo, idizili, amalahle, izinhlayiya ze-biomass, njll.

4. Ukulawula izinga lokushisa okuhlakaniphile.