Imikhiqizo

Isivinini esilungisekayo kanye ne-disperser yokusebenza ezinzile

Imininingwane Yomkhiqizo

I-disperser itholakala ngobukhulu obuhlukahlukene namamodeli, futhi izingxenye ezithintana nomkhiqizo, njenge-tank enyakazayo kanye ne-dispersing disc, zenziwe ngensimbi engagqwali. Ngokwezidingo zamakhasimende, amamotho angaqhumi angasetshenziswa njengamamotho okushayela.

Isivinini esiphezulu semishini singafinyelela ku-1450rpm, futhi isivinini somugqa singaphezu kuka-20m / s, esingahlakaza ngokushesha futhi ngokulinganayo i-powder ibe yinto ewuketshezi; impahla ihlakazeke ngokulinganayo ngenxa yamandla aphezulu kakhulu okugunda, okwenza umphumela omuhle we-Levitation.

Ngokuzungezisa ngesivinini esiphezulu sediski ehlakazayo, i-material igeleza ngendlela eyindilinga, ikhiqize i-vortex eqinile, futhi yehlele phansi kwe-vortex ngendlela ezungezayo. Umthelela onamandla we-shear kanye nokungqubuzana kukhiqizwa phakathi kwezinhlayiya ukuze kuzuzwe imisebenzi yokuhlakazeka okusheshayo, ukuqedwa, ukuxuba okufanayo kanye ne-emulsification.

I-hydraulic plunger ishayelwa phezulu naphansi yiphampu ye-hydraulic, ishayela yonke indlela yokudlulisela kanye neqembu elisebenzayo phezulu naphansi.

Isicelo

I-Disperser yakhelwe ukuxuba izinto eziqinile ezimaphakathi kumidiya ewuketshezi. I-Dissolver isetshenziselwa ukukhiqizwa kwamapende, ama-adhesives, imikhiqizo yezimonyo, ama-pastes ahlukahlukene, ama-dispersions nama-emulsions, njll.

Ama-dispersers angenziwa ngamakhono ahlukahlukene. Izingxenye kanye nezingxenye ezithintana nomkhiqizo zenziwe ngensimbi engagqwali. Ngokwesicelo sekhasimende, okokusebenza kusengahlanganiswa nedrayivu yokuvikela ukuqhuma

I-disperser ifakwe i-stirrer eyodwa noma ezimbili - uhlobo lwegiya eliphezulu noma uhlaka olunesivinini esiphansi. Lokhu kunikeza izinzuzo ekusetshenzisweni kwezinto ezibonakalayo ze-viscous. Futhi kwandisa ukukhiqiza kanye nezinga lekhwalithi lokuhlakazeka. Lo mklamo we-dissolver ikuvumela ukuthi ukwandise ukugcwaliswa komkhumbi kuze kufike ku-95%. Ukugcwalisa ngezinto ezigaywa kabusha kulokhu kugxila kwenzeka lapho ifaneli isuswa. Ngaphezu kwalokho, ukudluliswa kokushisa kuyathuthukiswa.

Umgomo wokusebenza kwe-disperser usekelwe ekusetshenzisweni kwe-milling mixer enesivinini esiphezulu ukugaya kahle umkhiqizo kuze kube yilapho kutholakala inqwaba ye-homogeneous.

Imininingwane Yomkhiqizo

01. Indawo yokubeka i-host 02. Injini enkulu 03. I-main shaft shaft hydraulic lifting, i-lift stroke 1.1M-1.6M 04. I-Stainless steel dispersion shaft 05. I-Hydraulic motor 06. Lawula ibhokisi likagesi 07. Ithangi likawoyela we-Hydraulic 08. I-Stainless steel dispersion shaft

I-SCOPE OF APPLICATION

I-high-speed disperser ifanele ukuxuba, ukusabalalisa, kanye nokuncibilikisa izinto eziwuketshezi neziqinile ezimbonini zamakhemikhali ezifana nezingubo, odayi, izingulube, noyinki.

1 kuya ku-1 isevisi eyenziwe ngokwezifiso

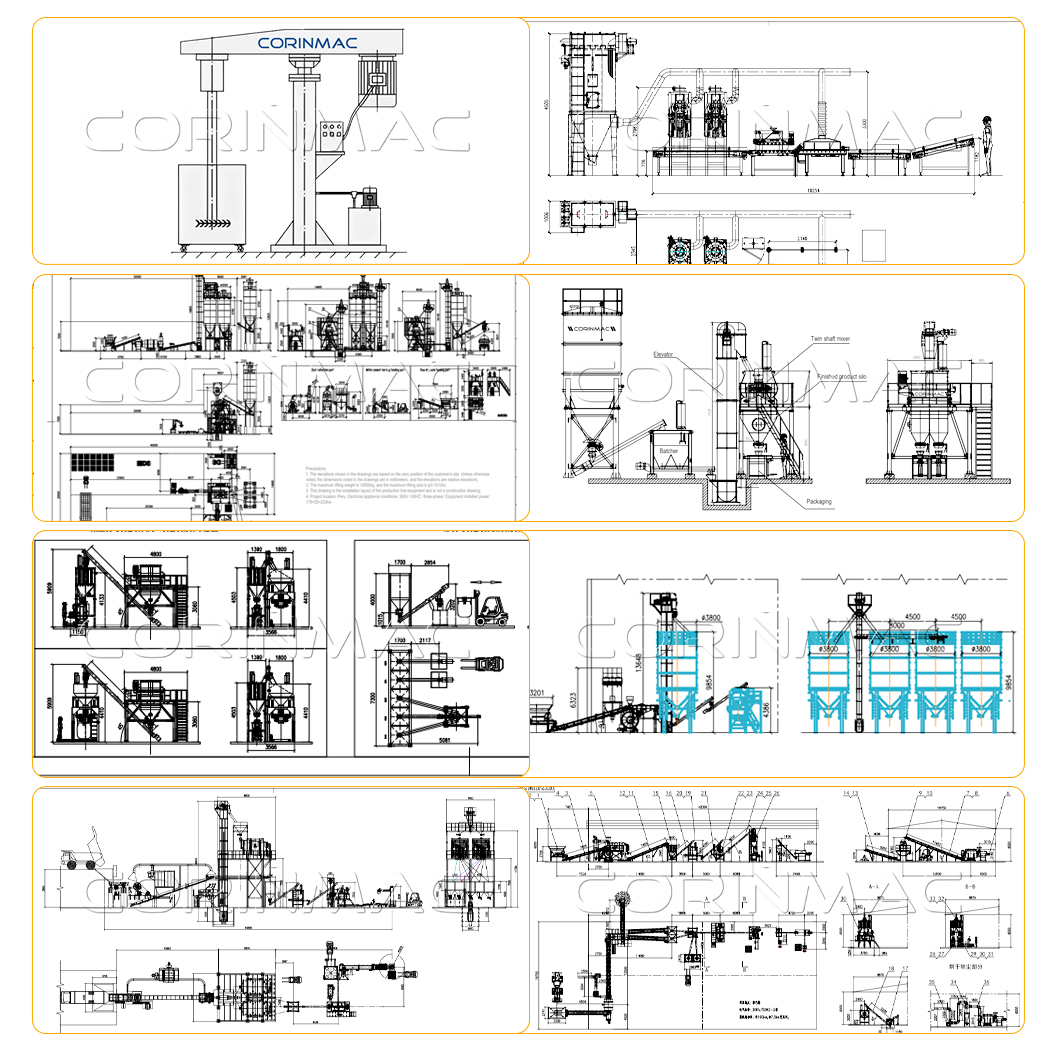

Singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho. Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nesakhiwo semishini yokukhiqiza.

Iphrojekthi Eyimpumelelo

Sinezingosi ezinezihloko eziningi emazweni angaphezu kwama-40 emhlabeni jikelele. Ingxenye yezingosi zethu zokufaka zimi kanje:

Amapharamitha

| Imodeli | Amandla | Isivinini sokuzungeza | Ububanzi be-Cutter | Umthamo wesitsha/Ukukhiqiza | Amandla e-hydraulic motor | Umsiki ephakamisa ukuphakama | Isisindo |

| FS-4 | 4 | 0-1450 | 200 | ≤200 | 0.55 | 900 | 600 |

| FS-7.5 | 7.5 | 0-1450 | 230 | ≤400 | 0.55 | 900 | 800 |

| FS-11 | 11 | 0-1450 | 250 | ≤500 | 0.55 | 900 | 1000 |

| FS-15 | 15 | 0-1450 | 280 | ≤700 | 0.55 | 900 | 1100 |

| FS-18.5 | 18.5 | 0-1450 | 300 | ≤800 | 1.1 | 1100 | 1300 |

| FS-22 | 22 | 0-1450 | 350 | ≤1000 | 1.1 | 1100 | 1400 |

| FS-30 | 30 | 0-1450 | 400 | ≤1500 | 1.1 | 1100 | 1500 |

| FS-37 | 37 | 0-1450 | 400 | ≤2000 | 1.1 | 1600 | 1600 |

| FS-45 | 45 | 0-1450 | 450 | ≤2500 | 1.5 | 1600 | 1900 |

| FS-55 | 55 | 0-1450 | 500 | ≤3000 | 1.5 | 1600 | 2100 |

| FS-75 | 75 | 0-1450 | 550 | ≤4000 | 2.2 | 1800 | 2300 |

| FS-90 | 90 | 0-950 | 600 | ≤6000 | 2.2 | 1800 | 2600 |

| FS-110 | 110 | 0-950 | 700 | ≤8000 | 3 | 2100 | 3100 |

| FS-132 | 132 | 0-950 | 800 | ≤10000 | 3 | 2300 | 3600 |

Iphrofayela Yenkampani

I-CORINMAC-Cooperation&Win-Win, lona umsuka wegama leqembu lethu.

Lesi futhi isimiso sethu sokusebenza: ngokusebenzisana ngokubambisana nokubambisana namakhasimende, dala inani labantu ngabanye kanye namakhasimende, bese siqaphela ukubaluleka kwenkampani yethu.

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeleni amakhasimende ethu izixazululo ezingcono kakhulu ngokunikeza amathuluzi ekhwalithi ephezulu kanye nemigqa yokukhiqiza yezinga eliphezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yekhasimende impumelelo yethu!

Ukuvakasha kwamakhasimende

Siyakwamukela ku-CORINMAC. Ithimba lochwepheshe le-CORINMAC likunikeza amasevisi aphelele. Kungakhathaliseki ukuthi uvela kuliphi izwe, singakunikeza ukwesekwa okucabangela kakhulu. Sinolwazi oluningi ezitshalweni zokukhiqiza udaka olomile. Sizokwabelana ngolwazi lwethu namakhasimende ethu futhi siwasize aqale amabhizinisi awo futhi enze imali. Sibonga amakhasimende ethu ngokusethemba nokusisekela!

Impendulo yomsebenzisi

Imikhiqizo yethu izuze idumela elihle nokuqashelwa emazweni angaphezu kuka-40, okuhlanganisa i-United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, njll.

Ukufakwa kanye nokugunyazwa

I-CORINMAC ihlinzeka ngezinsizakalo zokufakwa esizeni kanye nezokuthuma. Singathumela onjiniyela abangochwepheshe kusayithi lakho ngokuya ngezidingo zakho futhi siqeqeshe abasebenzi abasesiza ukuthi basebenzise imishini. Futhi singahlinzeka ngezinsizakalo zokuqondisa ukufakwa kwevidiyo.

Umdwebo

Imikhiqizo yethu

Imikhiqizo enconyiwe

Isivinini esilungisekayo kanye ne-disperser yokusebenza ezinzile

I-disperser inemisebenzi yokuhlakaza nokunyakazisa, futhi iwumkhiqizo wokukhiqiza ngobuningi; ifakwe i-frequency converter yokulawula isivinini esingenasinyathelo, esingasebenza isikhathi eside, ngokusebenza okuzinzile nomsindo ophansi; i-dissing disc ilula ukuhlakazeka, futhi izinhlobo ezahlukene zama-discs ezihlakazayo zingashintshwa ngokuvumelana nezici zenqubo; isakhiwo sokuphakamisa samukela isilinda se-hydraulic njenge-actuator, ukuphakamisa kuzinzile; lo mkhiqizo uyisinqumo sokuqala sokuhlakazeka nokuxuba okuqinile koketshezi.

I-disperser ifaneleka ukukhiqizwa kwezinto ezihlukahlukene, njengopende we-latex, upende wezimboni, uyinki osekelwe emanzini, i-pesticide, i-adhesive nezinye izinto ezine-viscosity engaphansi kwe-100,000 cps kanye nokuqukethwe okuqinile okungaphansi kuka-80%.

Buka OkuningiI-CRM Series Ultrafine Grinding Mill

Isicelo:i-calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverizing, ukulungiswa kwempuphu yamalahle, njll.

Izinto zokwakha:I-limestone, i-calcite, i-calcium carbonate, i-barite, i-talc, i-gypsum, i-diabase, i-quartzite, i-bentonite, njll.

- Amandla: 0.4-10t/h

- Ubuhle bomkhiqizo oqediwe: 150-3000 mesh (100-5μm)

Ikholamu engabizi kakhulu futhi emincane yekholomu...

Amandla:~500 izikhwama ngehora

Izici Nezinzuzo:

1.-Amathuba wokwenza i-palletizing kusuka ezindaweni ezimbalwa zokuthatha, ukuze ubambe izikhwama ezivela emigqeni yezikhwama ehlukene endaweni eyodwa noma ngaphezulu yokunamathisela.

2. -Amathuba wokwenza i-palletizing kuma-pallets abekwe ngqo phansi.

3. -Usayizi ohlangene kakhulu

4. -Umshini uhlanganisa uhlelo lokusebenza olulawulwa yi-PLC.

5. -Ngezinhlelo ezikhethekile, umshini ungenza cishe noma yiluphi uhlobo lohlelo lwe-palletizing.

6. -Ifomethi kanye nezinguquko zohlelo lwenziwa ngokuzenzakalelayo futhi ngokushesha okukhulu.

Isingeniso:

I-palletizer yekholomu ingabuye ibizwe ngokuthi i-Rotary palletizer, i-Single Column palletizer, noma i-Coordinate palletizer, iwuhlobo olufushane kakhulu noluhlangene lwe-palletizer. I-Column Palletizer ingakwazi ukuphatha izikhwama eziqukethe imikhiqizo ezinzile, ene-aerated noma eyimpuphu, evumela ukunqwabelana kwezikhwama kulwelwesi kukho kokubili phezulu nasezinhlangothini, okuhlinzeka ngezinguquko zefomethi eziguquguqukayo. Ubulula bayo obudlulele bukwenza kube nokwenzeka ukubamba i-palletise ngisho nakuma-pallets ahlezi ngqo phansi.

Ngezinhlelo ezikhethekile, umshini ungenza cishe noma yiluphi uhlobo lohlelo lwe-palletizing.

I-palletizer yekholomu inekholomu ejikelezayo eqinile enengalo evundlile eqinile exhunywe kuyo ekwazi ukuslayida ngokuma ihambisane nekholomu. Ingalo evundlile inesibambi sokulanda isikhwama esigibele kuso esishelelayo eduze kwaso, sizungeza i-eksisi yayo eqondile. Umshini uthatha izikhwama esisodwa ngesikhathi ku-roller conveyor ezifika kuso bese uzibeka endaweni eyabelwe uhlelo.Ingalo evundlile yehlela ekuphakameni okudingekayo ukuze isibambi singakwazi ukucosha isikhwama bese sithatha isikhwama njengesikhwama ukuvumela ukuzungezisa kwamahhala kwekholomu eyinhloko. I-gripper inqamula engalweni futhi izungeza ikholomu eyinhloko ukuze ibeke isikhwama endaweni eyabelwe iphethini ye-palletising ehleliwe.

Buka OkuningiUlayini wokukhiqiza udaka owomile wokulawula okuhlakaniphile ...

Izici:

1. Isistimu yokusebenza yezilimi eziningi, isiNgisi, isiRashiya, iSpanishi, njll. ingenziwa ngokwezifiso ngokuvumelana nezidingo zamakhasimende.

2. Isibonisi sokusebenza esibonakalayo.

3. Ukulawula okuhlakaniphile okuzenzakalelayo ngokugcwele.

Ukomisa ulayini wokukhiqiza usebenzisa amandla aphansi...

Izici Nezinzuzo:

1. Wonke umugqa wokukhiqiza wamukela isixhumi esibonakalayo sokulawula nokusebenza okubonakalayo.

2. Lungisa isivinini sokuphakelayo kanye nesivinini sokuzungeza isomisi ngokuguqula imvamisa.

3. Ukulawula okuhlakaniphile kwe-Burner, umsebenzi wokulawula izinga lokushisa ohlakaniphile.

4. Ukushisa kwezinto ezomisiwe zingama-60-70 degrees, futhi zingasetshenziswa ngokuqondile ngaphandle kokupholisa.