I-palletizer yekholomu engabizi kakhulu futhi emincane yezinyawo

Imininingwane Yomkhiqizo

Isingeniso

I-palletizer yekholomu ingabuye ibizwe ngokuthi i-Rotary palletizer noma i-Coordinate palletizer, iwuhlobo olufushane kakhulu noluhlangene lwe-palletizer. I-Column Palletizer ingakwazi ukuphatha izikhwama eziqukethe imikhiqizo ezinzile, ene-aerated noma eyimpuphu, evumela ukunqwabelana kwezikhwama kulwelwesi kukho kokubili phezulu nasezinhlangothini, okuhlinzeka ngezinguquko zefomethi eguquguqukayo. Ubulula bayo obudlulele bukwenza kube nokwenzeka ukubamba i-palletise ngisho nakuma-pallets ahlezi ngqo phansi.

Umshini unekholomu ejikelezayo eqinile enengalo evundlile eqinile exhunywe kuyo ekwazi ukuslayida ngokuma kukholomu. Ingalo evundlile inesibambi sokulanda isikhwama esigibele kuso esishelelayo eduze kwaso, sizungeza i-eksisi yayo eqondile. Umshini uthatha izikhwama esisodwa ngesikhathi ku-roller conveyor ezifika kuso bese uzibeka endaweni eyabelwe uhlelo.Ingalo evundlile yehlela ekuphakameni okudingekayo ukuze isibambi singakwazi ukucosha isikhwama bese sithatha isikhwama njengesikhwama ukuvumela ukuzungezisa kwamahhala kwekholomu eyinhloko. I-gripper inqamula engalweni futhi izungeza ikholomu eyinhloko ukuze ibeke isikhwama endaweni eyabelwe iphethini ye-palletising ehleliwe.

Ingalo ibekwe endaweni ephakeme edingekayo futhi into yokubamba ivula ukubeka isikhwama kuphalethi okwakhiwa. Kuleli qophelo, umshini ubuyela endaweni yokuqala futhi ulungele umjikelezo omusha.

Isixazululo esikhethekile sokwakha sinikeza i-palletizer yekholomu izici eziyingqayizivele:

Amathuba wokwenza i-palletizing kusuka ezindaweni ezimbalwa zokuthatha, ukuze ubambe izikhwama ezivela emigqeni yezikhwama ehlukene endaweni eyodwa noma ngaphezulu yokunamathisela.

Amathuba wokwenza i-palletizing kuma-pallets abekwe ngqo phansi.

Usayizi ohlangene kakhulu

Umshini unohlelo lokusebenza olulawulwa yi-PLC.

Ngezinhlelo ezikhethekile, umshini ungenza cishe noma yiluphi uhlobo lohlelo lwe-palletizing.

Ifomethi nezinguquko zohlelo zenziwa ngokuzenzakalelayo futhi ngokushesha okukhulu.

1 kuya ku-1 isevisi eyenziwe ngokwezifiso

Singenza imiklamo ehlukene yohlelo kanye nokucushwa ngokwezidingo zakho. Sizohlinzeka ikhasimende ngalinye ngezixazululo zokukhiqiza ezenziwe ngokwezifiso ukuze sihlangabezane nezidingo zezindawo ezahlukene zokwakha, ama-workshops kanye nesakhiwo semishini yokukhiqiza.

Iphrofayela Yenkampani

I-CORINMAC-Cooperation&Win-Win, lona umsuka wegama leqembu lethu.

Lesi futhi isimiso sethu sokusebenza: ngokusebenzisana ngokubambisana nokubambisana namakhasimende, dala inani labantu ngabanye kanye namakhasimende, bese siqaphela ukubaluleka kwenkampani yethu.

Kusukela yasungulwa ngo-2006, i-CORINMAC bekuyinkampani esebenza kahle futhi ephumelelayo. Sizibophezele ekutholeleni amakhasimende ethu izixazululo ezingcono kakhulu ngokunikeza amathuluzi ekhwalithi ephezulu kanye nemigqa yokukhiqiza yezinga eliphezulu ukuze sisize amakhasimende afinyelele ukukhula kanye nempumelelo, ngoba siqonda ngokujulile ukuthi impumelelo yekhasimende impumelelo yethu!

Ukuvakasha kwamakhasimende

Siyakwamukela ku-CORINMAC. Ithimba lochwepheshe le-CORINMAC likunikeza amasevisi aphelele. Kungakhathaliseki ukuthi uvela kuliphi izwe, singakunikeza ukwesekwa okucabangela kakhulu. Sinolwazi oluningi ezitshalweni zokukhiqiza udaka olomile. Sizokwabelana ngolwazi lwethu namakhasimende ethu futhi siwasize aqale amabhizinisi awo futhi enze imali. Sibonga amakhasimende ethu ngokusethemba nokusisekela!

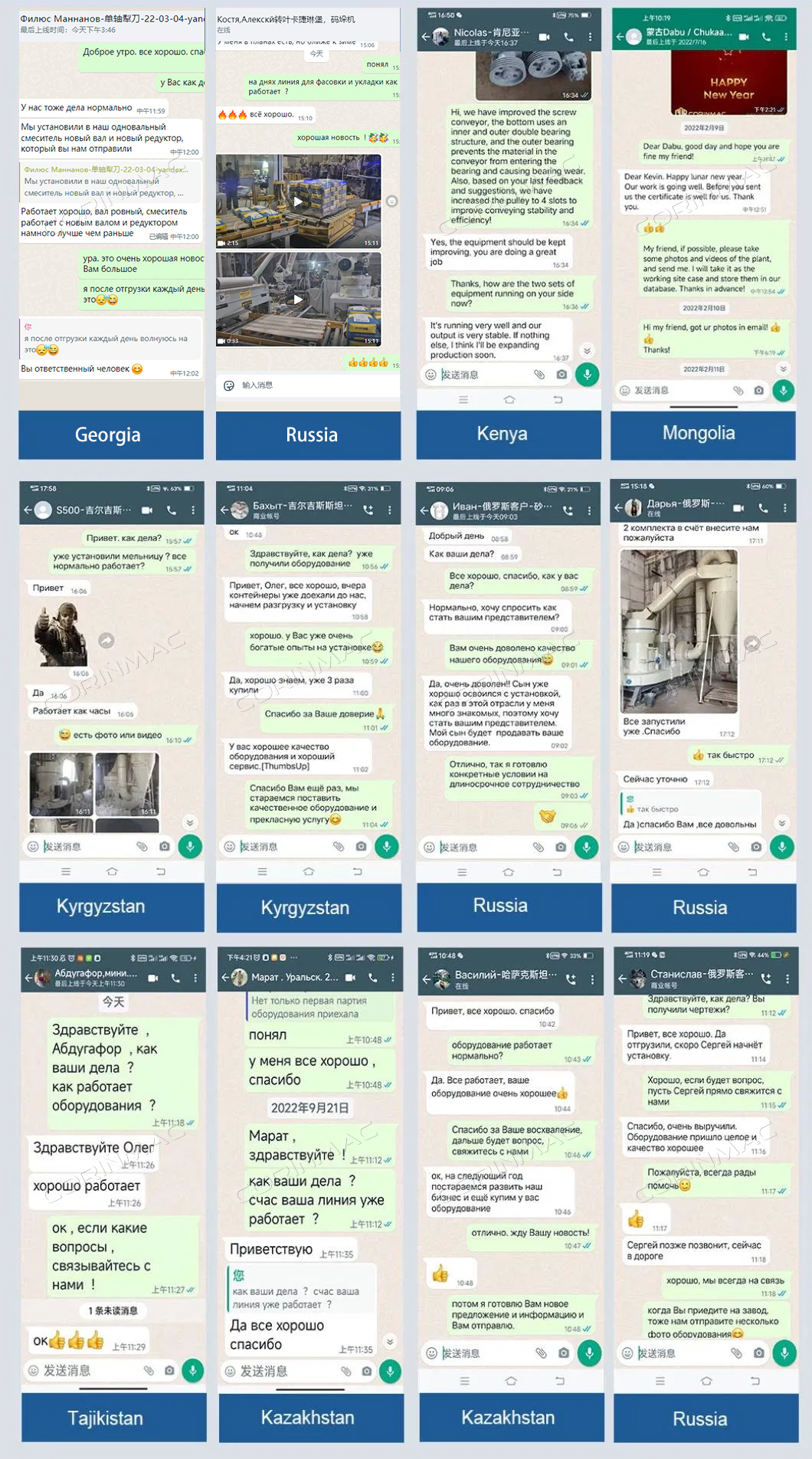

Impendulo yomsebenzisi

Imikhiqizo yethu izuze idumela elihle nokuqashelwa emazweni angaphezu kuka-40, okuhlanganisa i-United States, Russia, Kazakhstan, Kyrgyzstan, Uzbekistan, Turkmenistan, Mongolia, Vietnam, Malaysia, Saudi Arabia, United Arab Emirates, Qatar, Peru, Chile, Kenya, Libya, Guinea, Tunisia, njll.

Ukufakwa kanye nokugunyazwa

I-CORINMAC ihlinzeka ngezinsizakalo zokufakwa esizeni kanye nezokuthuma. Singathumela onjiniyela abangochwepheshe kusayithi lakho ngokuya ngezidingo zakho futhi siqeqeshe abasebenzi abasesiza ukuthi basebenzise imishini. Futhi singahlinzeka ngezinsizakalo zokuqondisa ukufakwa kwevidiyo.

Isiqondiso sezinyathelo zokufaka